February 18th, 2014by Kelli Lynn Hargrove (snowboardmag.com)

In 1977, Jake Burton began building snowboards in a barn in southern Vermont. In the 36 years since, Burton has maintained an ever-present influence in the snowboarding world, continuously creating and innovating new gear, while consistently pushing the boundaries of what is possible on-snow. Today, Burton’s products are tried and trusted, as can be gleaned by the stacked roster of riders that choose to use Burton gear, or the simple fact that Burton has remained an industry staple since the day it stepped onto — or rather, breathed life into — the snowboarding scene.

Now, with the realities of global warming and the mistreatment of the environment omni-present and weighing heavily upon the industry, the company is taking strides to become a fully sustainable brand. Jake’s wife, Burton Co-Owner and President Donna Carpenter explains that now, more than ever, she wants the company to be transparent, to utilize new materials and new methods of production to debut products that will help extend the life of snowboarding, instead of poisoning it.

Mission statements, like “Our commitment is to make Burton as respected for our environmental and social impact as we are for our products…to make snowboarding – and our lifestyle – sustainable well into the future,” can be found all over the brand’s website, and Carpenter wants to make sure that in making such statements, her company is in no way hypocritical; that they are not simply building up a garish facade of eco-friendly jargon and clever marketing schemes, but instead creating gear that lives up to their call for a cultural change.

Donna with Burton ripper Kimmy Fasani in Baldface | P: Susie Floros

The company is striving to be proactive, as opposed to reactive, meaning they are taking the reigns on improving their product, instead of waiting for something to go wrong and then retroactively addressing the issue. Initiatives have been implemented throughout the company, from the factories to HQ and on to the slopes, to help achieve Burton’s goal of overall waste reduction and the promotion of a truly eco-friendly lifestyle.

At company headquarters, for example, there are bikes available for workers to use, with the added incentive of free breakfast every Friday for those who make the choice to commute on two wheels instead of four. At its core, what Burton is pushing is a culture change, a way of thinking that breeds sustainable living, habits that help the environment, even if only on a micro-level. There have already been macro-results, however, as the company managed to reduce its waste by an impressive 50% over the course of just one year.

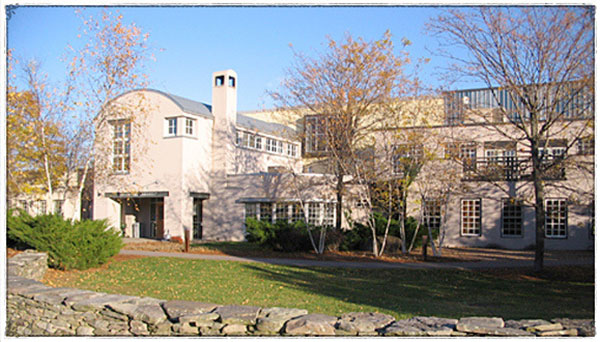

Burton’s Burlington Home | P: Burton

The real change is happening outside of office walls, however, as Donna and her athletes have stepped up as advocates for the environment. Carpenter, accompanied by Burton riders Danny Davis, John Jackson and members of Protect Our Winters (POW), took a trip to DC to speak personally with members of the senate about regulating power plants and controlling Carbon as a pollutant. The Natural Resources Defense Council (NRDC) worked alongside POW to compile data that highlights the economic effects that the lack of environmental regulation is having on mountain states, where shorter seasons, drought, and severe weather are having a dramatically negative effect on local economies.

Donna talks about feeling a responsibility to snowboarding, the need to protect and propel the industry and its frosted playground. She views the snowboarding industry, on the whole, as being a step behind in the sustainability game, a little slow on the up-take but now making serious strides and catching up. Burton, for its part, is working to pave a responsible path in the gear market, presenting a line up for 2015 that is nothing short of inspiring. From hard goods to accessories, the brand is churning out new shapes, designs, materials, and new manufacturing processes to ensure their products are on par with the lifestyle and culture the company itself is working to embody.

The brand has introduced FSC woodcores into their Family Tree collection, meaning that the wood used to create the core of each board was grown in a sustainable manner, traced from the source straight through until the boards hit shop floors. Additionally, the Family Tree boards now boast PET topsheets, made entirely from recycled plastic bottles, a process already used by many brands in creating outerwear, but one that is new to the hard goods realm.

Another exciting new initiative for Burton is the brand’s alignment with Bluesign, a system that unites the entire textile supply chain to ensure that from start to finish, no hazardous production methods are used. From testing the air and water quality in factories, to regulating the use of resources, Bluesign is a holistic approach to sustainable manufacturing.

At the end of the day, Burton is putting its money where its mouth is. Instead of spouting catchy phrases to give off eco-friendly vibes, Donna and her co-horts are personally advocating for climate change on both a small scale — their own offices, and those of US Senators— and on a larger stage, building out product lines with resource conscious methods and sustainable materials. This is what it looks like to fight for the soul of snowboarding, and cheers to Donna Carpenter for making it look so damn good.

No comments:

Post a Comment